The coffee roaster performs one of the most critical and essential steps in creating great gourmet coffee. The roasting process is responsible for developing and bringing out the full flavor of the coffee bean. Coffee roasting requires an expertise that takes time to develop.

Similar to grapes used to make wine, coffee bean characteristics vary significantly as a result of varietal, soil, climate, harvest, and growing technique. It takes a skilled craftsperson with a lot of experience to bring out the best qualities of the coffee beans during the roasting process. A master roaster is truly an artisan.

The roasting approach has a pronounced effect on the taste and flavor of the coffee beans. The type of roast has to be properly matched to the varietal of coffee bean. In general, there is an optimum roast for each different variety of coffee beans. Different beans will respond differently to the roasting process, requiring more or less heat and different durations through the roasting cycles. Roasting too slowly at too low of a temperature will rob the beans of their flavor. Roasting too quickly at too high of a temperature will burn or scorch the exterior of the beans.

An expert coffee roaster considers the weight, volume, water content and flavor characteristics of the beans in preparation for the optimum roast. Roasting is a fine art requiring split-second timing and the ability to judge when the coffee bean has been brought to its peak of flavor.

Type of Roasts

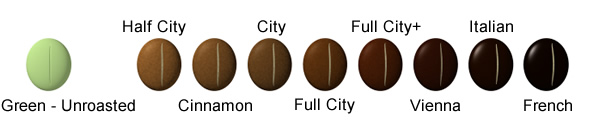

Here are some of the more common roasts from lightest to darkest.

- Very Light roast – also referred to as a Half-city roast, Cinnamon roast and New England roast. This roast produces a dryer coffee with a lighter flavor. Can sometimes be a bit grainy depending on the bean. The lightest roasts produce a tan or yellow colored bean.

- Light roasts - also referred to as City roasts and American roasts. These roasts typically produce a well-balanced coffee. The light roast produces a medium brown bean that stops short of bringing the natural oils to the surface.

- Medium roasts - also referred to as Full City, Vienna roasts and Continental roasts. As the medium roasts move to the darker range, some oils may begin to emerge at the surface.

- Dark roasts - also referred to as Italian roasts. The dark roast produces a darker brown bean and brings the bean’s natural oils to the surface. The darker roast adds a caramel or chocolate tone to the flavor.

- Darkest roasts - also referred to as heavy or French roasts. All hints of the underlying coffee bean’s characteristics generally give way to the heavy, smoky, over roasted result. Even more extreme is the Spanish roast, which is taken almost to the fire threshold, and has a distinct charcoal essence with a burnt and bitter aftertaste.

Coffee Rosting Chart - adapted from the Wikimedia Commons.

It’s a misconception that the darker the roast the better. Although the darker roasts are the current vogue, they’re not necessarily better. The darker the roast, the more the burnt quality of the roast tends to overshadow the underlying flavor qualities of the bean.

Darker roasts tend to have more of a predominant roast component to the flavor while lighter roasts tend to compliment more of the flavor characteristics of the coffee bean. Some single origins are definitely better suited to a light or medium roast.

The expert coffee roaster will produce roast levels or types of roasts that bring out the optimum flavor and quality of the beans.

Roasting Steps

Roasting is done at temperatures of up to 450F degrees. The coffee roaster determines the level or type of roast by controlling the duration and the temperature during the roasting process.

- Yellow phase – this is the first phase of the roasting process. The coffee beans take on heat until they rise to about 210F to 240F. The outer layer of the beans begins to discolor, turning a distinct yellow or cinnamon color. Steam will start being released from the beans. This release of moisture is the initial drying cycle.

- First Crack – as the temperature continues to rise between 250F and 300F, the external membrane of the bean will dry up and start separating from the bean itself. At approximately 350F, the heating of the bean forces a “first crack”. This audible cracking sound occurs as moisture is released forcing the separation of the remaining chaff that detaches from the bean. The structure of the bean begins to break down, sugars start to carmelize and the natural oils begin to migrate outward towards the surface of the bean.

After the first crack, this is the lightest usable roast level. At this stage, the bean is a light brown or cinnamon color, and also referred to as a “light city roast”.

The slightly darker “city roast” roast occurs above 370F and usually stopped before 400F. The sugars have carmelized further from a light city roast, but are not fully carmelized. At this stage, the flavor is determined much more by the bean’s origin than by the degree of roast.

The coffee roaster uses the audible sound of the first crack to help gauge what stage the roast is at.

- Second Crack – as the beans continue to heat up, carmelization continues, oils continue to migrate and the beans expand in size as the roast becomes darker. An audible “second crack” can be heard, sometimes more pronounced than the first. At second crack, the temperature of the beans reaches the point where the structure of the bean breaks down sufficiently, and small pieces of the bean are sometimes thrown off like shrapnel.

To obtain a “Full City Roast”, the coffee roaster stops the roast just as this second crack occurs at approximately 425F to 440F, although the precise temperature will vary based on the variety of the bean. At full city roast, the beans are a little darker than “City Roast”, but still dry looking on the surface, as the oils have not yet sweated out at the surface of the beans.

Going further into the second crack, further dehydration occurs as the beans continue to darken. The oils begin to come to the surface of the beans. The medium Vienna and Continental roasts occur past the second crack.

Allowing the roast to continue further past second crack produces the darker Italian and French roasts. As the roast becomes darker, the sugars within the bean are almost fully carmelized and many beans will have visual fissures on the surface.

Further roasting past the 15 minute mark will eventually burn the sugars completely, resulting in a very carbonized bean resembling charcoal.

- Finish – once the coffee roaster has achieved the desired level of roast, whether a light city roast just beyond first crack, or a very dark French roast well into second crack, it’s necessary to stop the roasting process quickly. The beans need to be immediately removed from the heat and allowed to cool as quickly as possible or the beans will continue to cook past the desired roast level.

This is usually accomplished by discharging the beans onto a cooling tray. A fan is often employed to draw cool air over the beans so that they cool evenly.

If you're curious, here are a few industrial coffee roasting equipment examples from Diedrich, a well known coffee roasting equipment manufacturer.